Engine Oil Mobil Delvac MX 15W-40 5L

-

Quick ShippingWith AED 20 only

-

Customer SupportCall Ghayar toll free

-

100% SafetyGuaranteed Genuine Products

-

Hot OffersDiscounts up to 50%

-

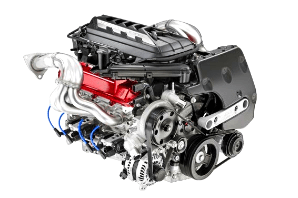

Features and Benefits

Mobil Delvac Extreme is formulated with synthetic base stocks and a boosted additive system tailored to deliver extended performance for up to two times beyond OEM recommended oil drain intervals1. The proprietary formulation delivers excellent wear protection, exceptional oxidation stability2, and outstanding TBN retention. Mobil Delvac Extreme FE also provides outstanding resistance to oil consumption, oxidation, corrosive and abrasive wear, and high temperature deposits.

1 Results may vary based on vehicle/engine condition, driving and environmental conditions Consult OEM or ExxonMobil before implementing extended ODIs.

2 Compared to an SAE 15W-40 conventional engine oil. Savings are dependent on vehicle engine type, outside temperature, driving conditions, and your current engine oil viscosity.

3 Based on performance in the Volvo T-13 engine test.

Applications

•Recommended for the latest heavy duty diesel engines operating in extreme conditions, including those equipped with aftertreatment systems and EGR.

• Recommended for diesel applications using older and naturally aspirated conventional designs.

• On-highway heavy-duty trucking and off-highway applications including trucking, mining, construction, agriculture and marine.

• On-highway applications operating in both high speed/high load and short haul pick-up/delivery service.

• Off-highway applications operating in severe low speed/heavy load conditions using up to 500 ppm sulfur fuels.

• Diesel-powered equipment from American, European and Japanese OEMs.

Properties and

Specifications

|

Property |

MOBIL DELVAC EXTREME 10W-30 |

MOBIL DELVAC EXTREME 15W-40 |

|

Grade |

SAE 10W-30 |

SAE 15W-40 |

|

Ash, Sulfated, mass%, ASTM D874 |

1 |

1 |

|

Cold-Cranking Simulator, Apparent Viscosity @ -20 C,

mPa.s, ASTM D5293 |

|

6100 |

|

Cold-Cranking Simulator, Apparent Viscosity @ -25 C,

mPa.s, ASTM D5293 |

6600 |

|

|

Density @ 15 C, g/ml, ASTM D1298 |

0.867 |

0.872 |

|

Flash Point, Cleveland Open Cup, °C, ASTM D92 |

219 |

221 |

|

Hi-Temp Hi-Shear Viscosity @ 150 C 1x10(6) sec(-1), mPa.s,

ASTM D4683 |

3.6 |

4.1 |

|

Kinematic Viscosity @ 100 C, mm2/s, ASTM D445 |

11.8 |

14.3 |

|

Kinematic Viscosity @ 40 C, mm2/s, ASTM D445 |

81.1 |

107.4 |

|

Mini-Rotary Viscometer, Apparent Viscosity, -30 C, mPa.s,

ASTM D4684 |

18400 |

|

|

Mini-Rotary Viscometer, Yield Stress, -25 C, Pa, ASTM

D4684 |

|

16900 |

|

Pour Point, °C, ASTM D97 |

-42 |

-33 |

|

Total Base Number, mgKOH/g, ASTM D2896 |

10.3 |

10.3 |

|

Viscosity Index, ASTM D2270 |

140 |

140 |